Foldable plastic packaging offers a versatile solution for businesses seeking efficient and adaptable packaging options. Customization in packaging plays a crucial role in enhancing brand identity and meeting specific consumer needs. Foldable plastic packaging provides several benefits, including space-saving design and ease of transportation. The lightweight nature of this packaging type reduces shipping costs. The durability of foldable plastic box packaging ensures product protection during transit. Businesses can leverage customization to create unique designs that resonate with their target audience

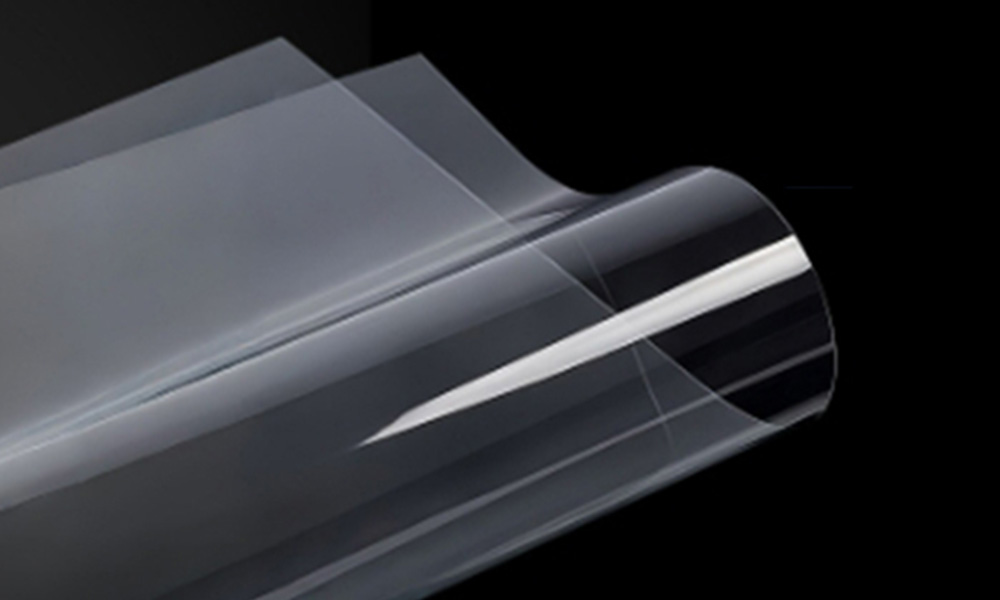

Foldable plastic packaging serves as a dynamic solution for various industries. The design allows the packaging to collapse when not in use. This feature optimizes storage space and reduces transportation costs. Manufacturers often use materials like polypropylene and polyethylene for creating foldable plastic packaging. These materials provide flexibility and durability. The lightweight nature of foldable plastic packaging enhances its appeal for businesses.

The structure of foldable plastic packaging incorporates hinges or creases. These elements enable the packaging to fold efficiently. The ability to fold relies on the material's flexibility. High-quality plastics ensure repeated folding without damage. The engineering behind foldable plastic packaging focuses on maintaining structural integrity. Businesses benefit from the ease of handling and storage.

Common materials for foldable plastic packaging include polypropylene and polyethylene. Polypropylene offers excellent chemical resistance and durability. Polyethylene provides flexibility and impact resistance. Both materials contribute to the lightweight nature of foldable plastic packaging. The choice of material impacts the packaging's performance and cost-effectiveness. Businesses select materials based on specific needs and environmental considerations.

Foldable plastic packaging comes in various forms to suit different applications. Each type offers unique advantages for businesses.

Foldable plastic boxes provide a versatile option for packaging. These boxes offer easy assembly and disassembly. The design maximizes storage efficiency. Businesses use foldable plastic boxes for shipping and retail purposes. The boxes protect products during transit and display.

Foldable plastic containers serve industries requiring bulk storage solutions. These containers offer high load-bearing capacity. The collapsible design saves space when not in use. Industries such as agriculture and manufacturing utilize foldable plastic containers. The containers ensure efficient storage and transportation.

Foldable plastic bags offer convenience for retail and promotional purposes. The bags provide a lightweight and portable packaging solution. Businesses customize foldable plastic bags with logos and designs. The bags enhance brand visibility and customer engagement. The versatility of foldable plastic bags makes them popular across various sectors.

Customizing foldable plastic packaging plays a significant role in enhancing brand recognition. Businesses can incorporate unique designs and logos on the packaging. These elements create a strong visual identity for the brand. Customers easily recognize products with distinctive packaging. The use of custom designs elevates the brand's market presence.

Custom designs on foldable plastic packaging allow businesses to showcase their creativity. Logos serve as a powerful tool for brand identification. A well-designed logo on packaging attracts consumer attention. The strategic placement of logos enhances visibility. Custom designs and logos contribute to a memorable brand experience.

Color schemes and themes on foldable plastic packaging influence consumer perception. Businesses select colors that align with brand values. Consistent color themes create a cohesive brand image. Vibrant colors capture consumer interest. The right color scheme enhances the overall appeal of the packaging.

Customization of foldable plastic packaging leads to improved functionality. Tailored sizes and shapes cater to specific product requirements. User-friendly features enhance the consumer experience. Functional packaging solutions meet diverse industry needs.

Tailored sizes and shapes in foldable plastic packaging offer flexibility. Businesses can design packaging to fit unique product dimensions. Custom sizes maximize storage efficiency. The adaptability of shapes accommodates various product types. Tailored packaging ensures optimal product protection.

User-friendly features in foldable plastic packaging improve usability. Easy-to-open designs enhance consumer convenience. Features like resealable closures maintain product freshness. Ergonomic handles facilitate easy transportation. User-friendly packaging increases customer satisfaction.

Businesses increasingly prioritize eco-friendly materials in foldable plastic packaging. These materials reduce environmental impact and appeal to environmentally conscious consumers. Biodegradable plastics offer a sustainable alternative to traditional options. Recycled materials contribute to a circular economy. Companies can enhance brand reputation by choosing eco-friendly packaging solutions.

Durability remains a critical factor in material selection for foldable plastic packaging. High-quality materials ensure long-lasting performance. Polypropylene provides excellent durability for various applications. Polyethylene offers impact resistance and flexibility. Businesses must assess material strength to meet specific packaging requirements. Durable packaging protects products during transit and storage.

Printing methods play a vital role in customizing foldable plastic packaging. Digital printing offers high-quality results with vibrant colors. Flexographic printing suits large-scale production needs. Screen printing provides versatility for different designs. Each method offers unique advantages for branding purposes. Businesses select printing techniques based on budget and design complexity.

Embossing and debossing add texture to foldable plastic packaging. Embossing raises design elements for a tactile experience. Debossing creates recessed patterns for subtle elegance. These techniques enhance visual appeal and brand differentiation. Businesses use embossing and debossing for logos and decorative elements. The choice of technique depends on desired effects and material compatibility.

Collaboration with designers plays a crucial role in developing effective foldable plastic packaging. Designers bring creativity and technical expertise to the table. Businesses must clearly communicate their brand vision and packaging requirements. Designers translate these ideas into functional and aesthetically pleasing designs. Regular meetings ensure alignment between business goals and design execution. Feedback from both parties refines the packaging design.

Prototyping and testing validate the design of foldable plastic packaging. Prototypes provide a tangible representation of the final product. Businesses can assess the packaging's appearance and functionality through prototypes. Testing evaluates the durability and performance of the packaging under various conditions. Feedback from testing informs necessary adjustments to the design. Successful prototyping and testing lead to a reliable and market-ready product.

Manufacturing timelines impact the overall production of foldable plastic packaging. Businesses must establish clear timelines to meet market demands. Efficient planning ensures timely procurement of materials and resources. Manufacturers adhere to schedules to avoid delays in production. Regular monitoring of progress helps maintain adherence to timelines. Meeting manufacturing timelines enhances customer satisfaction and business reputation.

Quality control measures ensure the consistency and reliability of foldable plastic packaging. Businesses implement stringent quality checks at every stage of production. Inspections verify the integrity and functionality of the packaging. Quality control teams identify and rectify defects promptly. Maintaining high standards in quality control builds trust with consumers. Consistent quality in packaging reflects positively on the brand image.

Customization in foldable plastic packaging holds immense importance. Businesses can enhance brand recognition and functionality through tailored designs. Exploring diverse customization options empowers companies to meet unique consumer needs. Engaging with experts in packaging design and production offers valuable insights. Consultation with professionals ensures optimal results in packaging solutions.